By Anurag S Rathore; G K Sofer

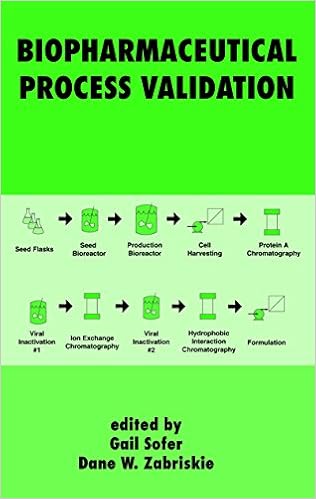

content material: instructions to strategy Validation, G. Sofer functions of Failure Modes and results research to Biotechnology production strategies, R.J. Seely and J. Haury procedure Characterization, J.E. Seely Scale-Down versions for Purification approaches: methods and functions, R. Godavarti, J. Petrone, J. Robinson, R. Wright, and B.D. Kelley Adventitious brokers: issues and trying out for Biopharmaceuticals, R. Nims, E. Presente, G. Sofer, C. Phillips, and A. Chang lifestyles Span experiences for Chromatography and Filtration Media, A.S. Rathore and G. Sofer Validation of a Flitration Strap, J. Campbell Analytical try out equipment for Well-Characterized organic and Biotechnological items, N. Ritter and J. McEntire Facility layout Issues-A Regulatory viewpoint, N. Roscioli and S. Vargo Validation of automatic structures, M.J. Cahilly approach Optimization and Characterization experiences for Purification of an E. coli-Expressed Protein Product, A.S. Rathore Validation of the ZEVALINO Purification procedure - A Case examine, L. Conley, J. McPherson, and J. Thommes procedure Validation of a Multivalent Bacterial Vaccine: a unique Matrix method, N.S. Pujar, M.G. Gayton, W.K. Herber, C. Abeygunawardana, M.L. Dekleva, P.K. Yegneswaran, and A.L. Lee Viral Clearance Validation: A Case learn, M. Rubino, M. Bailey, J. Baker, J.A. Boose, L. Metzka, V. Moore, M. Quertinmont, and W. Wiler in regards to the editors... ANURAG S. RATHORE is a Scientist in approach improvement, Amgen Inc., Thousand Oaks, California. His staff is chargeable for the aid of technique improvement, method characterization, scale-up, creation, and approach validation of overdue level items. ahead of becoming a member of Amgen Inc., he held an analogous place at Pharmacia company. Dr. Rathore has authored greater than 50 courses and displays and is sequence editor of the Biotechnology and Bioprocessing sequence for Marcel Dekker. he's the editor of numerous contemporary books together with Scale-up

Read or Download Process validation in manufacturing of biopharmaceuticals : guidelines, current practices, and industrial case studies PDF

Best pharmacy books

Free Energy Calculations in Rational Drug Design

Loose power calculations signify the main exact computational approach to be had for predicting enzyme inhibitor binding affinities. Advances in laptop strength within the Nineteen Nineties enabled the sensible program of those calculations in purpose drug layout. This ebook represents the 1st complete evaluate of this starting to be quarter of study and covers the fundamental conception underlying the tactic, a number of cutting-edge options designed to enhance throughput and dozen examples in which loose strength calculations have been used to layout and assessment capability drug applicants.

The School of Pharmacy, University of London. Medicines, Science and Society, 1842–2012

The varsity of Pharmacy, collage of London: medicinal drugs, technological know-how and Society, 1842-2012 represents the wealthy heritage of the collage of London tuition of Pharmacy via a number of colour images, vital advances within the pharmacy occupation, cultural milestones, biographies and extra. Written in a fascinating and authoritative kind, this e-book depicts the chronological historical past of the varsity from its institution in 1842 to the current day with a nod towards its aspirations for the long run.

This quantity presents the reader with contemporary advances within the fields of molecular toxinology, the biotechnological functions of venom pollutants, and antivenom creation. The content material of the twenty chapters of Venom Genomics and Proteomics illustrates not just the big growth made because the implementation of omics applied sciences within the box of toxinology, yet one additionally realizes the line nonetheless forward to arrive a holistic view of venomous structures.

Pharmaceutical Process Scale-Up

Targeting medical and functional facets of technique scale-up, this source info the idea and perform of shifting pharmaceutical techniques from laboratory scale to the pilot plant and creation scale. It covers parenteral and nonparenterel beverages and semi-solids, items derived from biotechnology, dry mixing and powder dealing with, granulation and drying, fluid mattress functions, compaction and tableting, and movie coating and regulatory standards for scale-up and postapproval adjustments.

Additional info for Process validation in manufacturing of biopharmaceuticals : guidelines, current practices, and industrial case studies

Example text

15 FMEA Worksheet .......................................................... 16 Evaluation Criteria: Severity, Occurrence, and Detection................................................................. 1 Severity ............................................................... 2 Occurrence........................................................... 3 Detectability........................................................ 6 Example of FMEA Applied to Process Transfer ......... 7 Next Steps......................................................................

The FMEA has resulted in (1) documentation that every element of the process (for characterization or for transfer) has been evaluated by a team, and (2) a prioritization of parameters or issues that now need to be addressed. Based on the RPNs, as visualized in Pareto fashion, the team should agree on a cutoff value for studying the “high” RPNs first, and perhaps some or all of the others as time and resources permit. As previously mentioned, this cutoff can be made prospectively (although for a biological process, this may be difficult and is not necessary), or it can be made retrospectively based on the results.

M. J. M. I. L. I. L. 3 Unit Operation Temperature mapping studies Current Controls 2 0 20 0 Detection RPN 24 Seely and Haury Fermentor R-0180 seal/ pressure Innoc. vial handling B. W. Contamination B. W. Leakage Handling of vials B. D. from freezer to plant will be equivalent to B-7 Assembly and maintenance Utility failure Inadeq. ster. cycle 10 10 10 Utility failure 4 Design Assembly and maintenance 4 10 Design 4 2 2 5 5 100 40 0 Applications of Failure Modes and Effects Analysis 25 26 Seely and Haury streamlined version of those provided in the references for the more “classical” FMEA applications.